- OBJECTIVE:

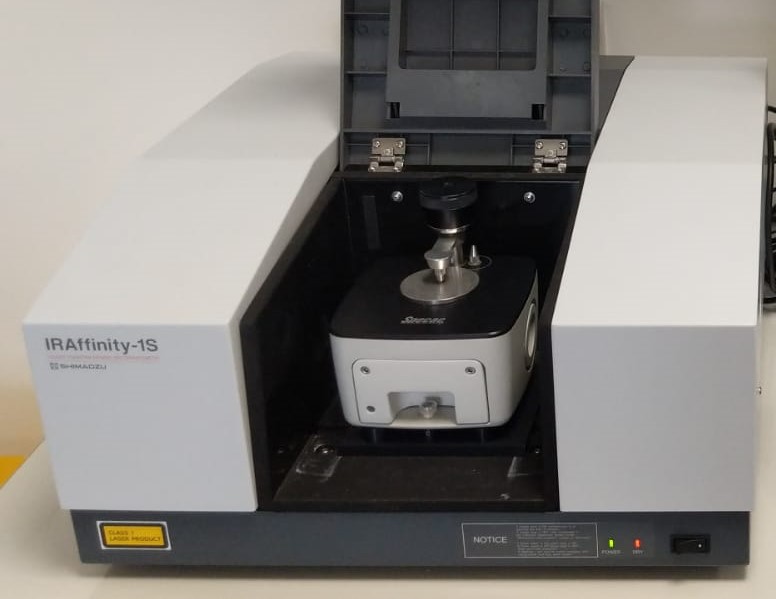

The purpose of this SOP is to lay down a procedure for operating, calibration, maintaining and cleaning of the FTIR Spectrophotometer.

- SCOPE:

This SOP is applicable to FTIR spectrophotometer (Make: Bruker, Model: Alpha – E) at Quality Control Department at manufacturing facility.

- RESPONSIBILITY:

- Analyst or his designee shall be responsible for follow the SOP.

- The Head of Quality Control Department or his designee shall be responsible and implementation of the SOP.

- PROCEDURE:

- Ensure that the instrument calibration is valid.

- Switch ON the Mains Switch of the Bruker Alpha.

- Switch ON the Computer and double click on OPUS Icon.

- Enter the Password.

- Detach the normal Transmission and attach the ATR Accessories.

- Once you log on to the OPUS software, you please wait for 10 minutes. Since the instrument is performing PQ test.

- Click on Measurement in this option selects Setup. Measurements configure the required settings; select the Path where you want to store your recorded spectrum. After changing the required settings click on save and exit.

- Now select on measurement and perform the sample back Ground measurement. Once this is over

- Place only the powdered samples on the top of ZnSe Crystal and move the top holder to the middle of the ZnSe crystal, Where the samples are placed and make it hand tight.

- Now select the Sample Measurements and wait until the scan is over.

- Once the scan is over you will see a spectrum in absorbance Mode.

- Now select the conversion of Absorbance to Transmission and change the Spectrum to Transmission.

- In the spectrum window bring your mouse and right click. In this option select scale all and show everything, now you can see the spectrum in TR. In the measurement you can do smooth, Normalization, Atmospheric correction.

- After doing the modification you can do Peak peaking in Evolution, take the print out go to print and select quick print for printout.

- SAMPLE PREPARATION FOR SAMPLES IN SOLUTION

- Prepare the solution in a suitable solvent.

- Choose a concentration and a path length of the cell as per the method procedure.

- The procedure to be followed as similar as powder the samples.

- Fill the sample solution and scan.

- The spectrum should not be modified for quantification tests.

- Calibration

- Verification of the Wave-number scale

- Operate the instrument as per operation procedure as per 4.1 to 4.14

- Place polystyrene film in sample compartment.

- After scanning, result shall be display with following details.

a) Form of power spectrum

b) Resolution, wave number accuracy and reproducibility test by polystyrene film.

- Check the peak value with peak value mentioned in below table.

Transmission minima (cm-1) Acceptable Tolerance

3060.0 ± 1.0

2849.5 ± 1.0

1942.9 ± 1.0

1601.2 ± 1.0

1583.0 ± 1.0

1154.5 ± 1.0

1028.3 ± 1.0

- Control of resolution performance:

- The difference between the absorbance at the absorption minimum at 2870 cm-1 and the absorption maximum at 2849.5 cm-1 is greater than 0.33. The difference between the absorbance at the absorption minimum at 1589 cm-1 and the absorption maximum at 1583 cm-1 is greater than 0.08.

- Record all the calibration data in Annexure-I.

- If the calibration of instrument is ok, affix a calibration status label.

- When the instrument does not comply with the requirement/acceptance criteria, the instrument shall be labeled as under maintenance.

- Frequency: Quarterly

- CLEANING PROCEDURE

- Clean the surface of the instrument with clean dry soft cloth.

- No solvents should be used for cleaning the instrument. If any solvent enters into the instrument, switch off and contact Bruker service people.

- The sample compartment should be cleaned with clean soft cloth. The sample path windows are made of potassium bromide. Don’t wipe the windows. Those windows should be cleaned by the Bruker service people only.

- SAFETY AND MAINTENANCE PROCEDURE

- The sample preparation place should be dry. If necessary use the Helium Neon lamp to keep the area dry.

- The liquid cells should be handled very carefully. If the sample solution contains water, the cells may be permanently damaged. Use Sodium sulphate anhydrous to dry the solvents.

- Never purge the instrument with flammable gases. Only use clean, dry oil-free nitrogen to purge the instrument.

- TRAINING:

Trainer : Head – Quality Control

Trainees : Quality Control chemist / Sectional Heads

- DISTRIBUTION:

Controlled Copy No.1: Head of Department – Quality Assurance

Controlled Copy No. 2: Head of Department – Quality Control

Original Copy : Head – Quality Assurance

- ANNEXURE:

Annexure I : Calibration Data sheet for FTIR Spectrophotometer

- REFERENCES(S):

Nil

- REVISION HISTORY:

| Sr. No. | Revision No. | Change Control Number | Details of Revision | Reasons(s) for Revision |

| 1 | 00 | —- | New SOP | New SOP |